Our Capabilities

Over the years, Allied Tech have developed our core capabilities from a metal specialist into a vertically integrated precision manufacturing service including design and product development, prototyping services, tool and die fabrication, plastic injection moulding, mechanical sub-assembly and metal surface finishing services.

-

Product Design & Development

-

Prototyping and Soft Tool Manufacturing

-

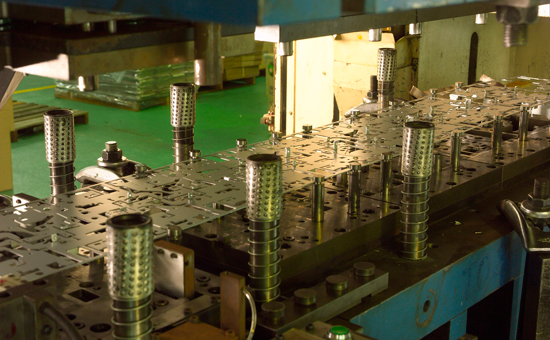

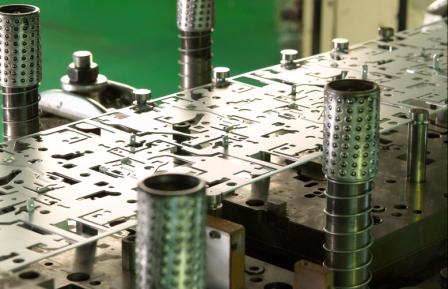

Tool & Die Design and Fabrication

-

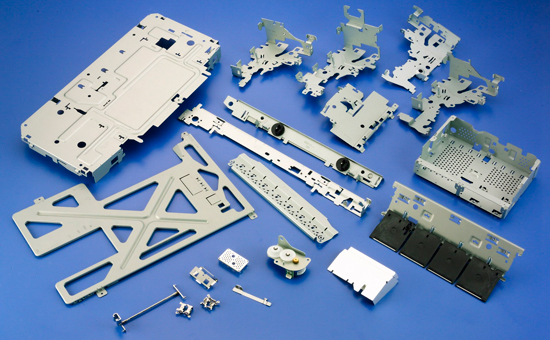

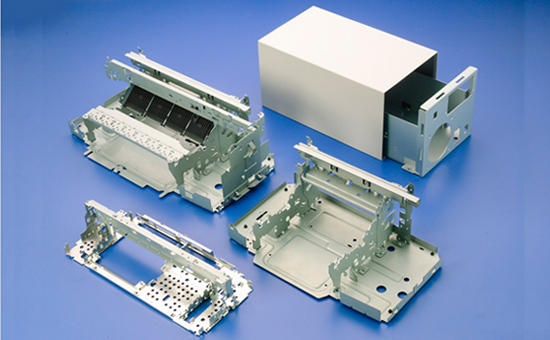

Precision Metal Stamping

-

Plastic Injection Moulding

-

Component Surface Finishing Process (Powder Coating, Anodising, Electrochemical process on metal components)

-

Mechanical Assembly

-

Surface Mount Technology Process

-

Full progressive tools for precision parts range from 45 tons to 400 tons power presses.

-

In-Die tapping; In-Die Insertion, In-Die Tapping, In-Die Assembly

-

Milling process; Printer product, Tape recorder